The role of fat in ice cream

If you find the content on this blog useful and would like to support my work, please consider doing so on Patreon.

11 MINUTE READ

Ice cream generally contains seven categories of ingredients: milk fat, milk solids-not-fat (the lactose, proteins, minerals, water-soluble vitamins, enzymes, and some minor constituents), sweeteners, stabilizers, emulsifiers, water, and flavours. In this post, we'll be looking at the role of fat in ice cream.

You might also like to read:

Cuisinart ICE-70 Ice Cream Maker - A comprehensive reviewLello 4080 Musso Lussino Ice Cream Maker - A comprehensive reviewLocust bean gum in ice creamWhy is corn syrup used in ice cream?How to calculate an ice cream mix[toc]Fat modifies the release and perceived intensity of flavour, increases the richness of flavour, is a good carrier of fat-soluble (i.e. those that dissolve easily in fat) flavours, produces smooth texture by lubricating the palate, helps to prolong shelf life by reducing recrystallisation rates during storage, aids in producing desirable melting properties, and contributes to the stability of air bubbles,([^1] [^2] [^3] [^4] [^5]).

1. The effect of fat on flavour

Flavour can be best defined as a combination of taste, odour, texture, temperature, sight, and even sound, experienced by an individual when eating or drinking. Flavour results from two types of molecules: those that are volatile (i.e. small and light enough to evaporate from their source), which are responsible for odours; and those that are non-volatile (i.e. don't easily evaporate at room temperature), which are responsible for taste.

TASTE AND ODOUR

When we eat and drink, volatile food molecules fly out of the food and into the air in our mouth, which allows them to rise into the nose as we breath out, particularly just after swallowing, where they are detected. Non-volatile molecules, on the other hand, cannot be easily smelled and must be dissolved in saliva to be detected by molecular receptors located in the taste buds on the tongue, and to a degree on the sides and back of the mouth, to give food its taste. Taste refers to five perceptions: salty, sweet, sour (acidic), bitter, and umami. These five perceptions are perceived much more slowly than odour ([^6]). It is generally believed that aroma is more important than taste in determining overall flavour, a generalisation that can be easily demonstrated by observing the difficulty in distinguishing between an apple and a pear if our nose is blocked by a cold or pinching fingers.

1.1. The effect of fat on taste and odour

Fat influences the rate of flavour release, the perceived flavour intensity, and the duration of flavour. Generally speaking, a higher fat content leads to a slower release of flavour, lower flavour intensity, and a longer duration of flavour ([^7] [^8] [^9] [^10]).

1.1.1. Flavour release

Most volatile odour molecules are lipophilic (i.e. they dissolve better in fat than in water); this is why cooks make prepared flavour extracts by infusing herbs and spices in oil, not water. Fat binds (hangs on to) these dissolved volatile odour molecules during eating so that their odour appears more gradually and persists longer. In the absence of fat, lipophilic odour molecules are poorly bound to the food, which means that relatively more volatile odour molecules are released into the mouth, giving sorbets, fat-free, and low-fat ice creams a faster release of flavour that disappears more quickly.

Frost et al.[^10] examined ice creams with different fat levels (3%, 6%, and 12% milk fat) and flavourings (berry, coconut, banana, and vanilla). The researches showed faster increases and decreases in flavour perception with lower fat levels.Similarly, Li et al.[^8] showed that increasing fat concentration (0.5%-10%) prolonged the time required to reach maximum vanilla intensity.

1.1.2. Flavour intensity

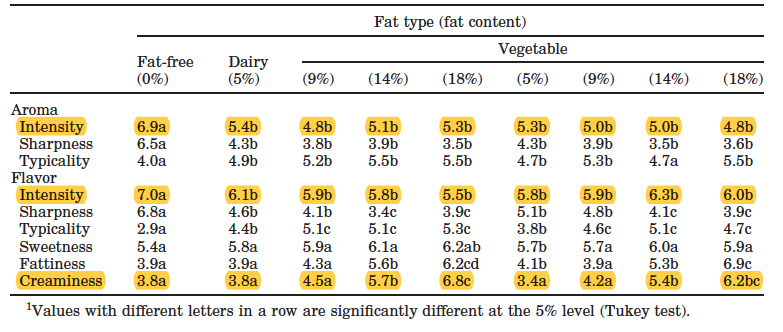

The amount of flavour released from food depends on the retention of volatile odour molecules by the food's components. Fat holds onto volatile odour molecules during eating so that more odour molecules go down the throat with the fat rather than travelling up into the nose with the breath. Fat also coats taste receptors in the mouth, thereby hindering taste molecules from moving to the taste buds. There is, therefore, a reduction in the perceived flavour intensity with increasing fat content. Conversely, as the fat content is decreased, more volatile odour molecules are released from food, thereby increasing the maximum flavour intensity. This point has a practical application for ice cream producers as the amount of flavour added to an ice cream mix with a lower fat content can be lower than that added to one with a higher fat content to trigger the same flavour release ([^11]). Hyvonen et al.[^12] investigated the effects of dairy and vegetable fats (0% to 18%) on the perception of strawberry flavour release and melting of ice cream. Significant differences in aroma and flavour were perceived between fat-free and fat-containing ice creams: intensity and sharpness of strawberry aroma and flavour were greater in the fat-free samples. However, the researchers found only slight effects of fat content on the rate of flavour release and flavour intensity between low fat (9%) and high fat (18%) strawberry-flavoured ice creams. Similarly, Li et al.[^8] did not find a significant effect of fat on the maximum intensity of vanilla with increasing fat concentration (0.5%-10%). The table below shows the ratings for nine sensory attributes of nine strawberry-flavoured ice cream samples containing different fat type and fat content. From Hyvonen et al.[^12].

1.2. Source and carrier of flavour

Milk fat is both a source and carrier of flavour. As a source of flavour, milk fat contributes significantly to the buttery, creamy, and ‘rich’ flavour of ice cream ([^13]). Moreover, milk fat reacts with sugars and proteins, yielding sugary and caramel-like notes in full-fat ice creams ([^14]). As previously mentioned, most volatile odour molecules dissolve better in fat than in water; only a small portion of volatile odour molecules are hydrophilic (i.e., they dissolve better in water). This makes milk fat the main carrier of added flavours.

2. Smooth and creamy texture

Ice crystal size is a critical factor in the development of smooth and creamy ice cream ([^16]). Smooth and creamy ice cream requires the majority of ice crystals to be small. If many crystals are large, ice cream will be perceived as being coarse or icy. Milk fat contributes to the smooth and creamy texture of ice cream by lubricating the palate, thereby reducing the perception of coarseness due to large ice crystals. Prindiville et al.[^5] investigated the effect of different fat contents (0.5%, 4%, 6%, and 9%) on the sensory properties of chocolate ice cream. The researchers found that the two ice creams containing the most fat were significantly creamier and smoother than were the other ice creams. Similarly, in a study of the influence of fat, sugar, and non-fat milk solids on taste, flavour, and texture, Stampanoni Koeferli et al.[^13] reported that the addition of fat increased buttery, creamy, and mouth-coating characteristics and reduced ice crystal perception.

2.1. Optimum fat content for flavour and texture

McCandlish et al.[^26] predicted optimum levels of fat for overall, flavour, and texture preferences to be 11.75%, 13.51%, and 10.2% respectively. Guinard et al.[^15] found optimum levels of sugar and fat in vanilla ice cream were 14.3% and 14.8% for overall liking, 14.1% and 15.4% for flavour liking, and 13.2% and 14% for texture/mouthfeel liking. In my tests, I've found 23% milk fat to be optimum for texture for homemade ice cream.

3. Reduce recrystallisation during storage

During storage, ice and lactose crystals grow and undergo recrystallisation. Recrystallisation is defined as “any change in number, size, shape… of crystals [during storage]” ([^17]) and basically involves small crystals disappearing, large crystals growing, and crystals fusing together. This increase in crystal size eventually reaches a point where the ice cream develops coarse texture, at which point it has surpassed its shelf life. Ice creams containing a higher concentration of milk fat have a lower sensory perception of coarseness after storage ([^5] [^13]). Fat globules mechanically obstruct the growth of ice crystals, thereby slowing the rate of recrystallisation and extending shelf life ([^16]).

4. Melting rate

Increasing the fat level has been shown to reduce the rate at which ice cream melts during consumption ([^10] [^13] [^15]).

5. Stabilise air bubbles

During dynamic freezing, where the ice cream mix is frozen in an ice cream machine whilst being agitated by the folding and mixing action of the rotating dasher and scrapper blades, the ice cream mix undergoes partial coalescence, where clumps and clusters of the fat globules form and build an internal fat structure or network by trapping air within the coalesced fat. These fat globule clusters are responsible for stabilising the air cells, thus preventing them from recombining and forming larger air bubbles ([^18] [^19] [^20]). This results in the beneficial properties of dryness, smooth and creamy texture, and resistance to meltdown ([^21] [^22] [^23] [^24]). Ice cream mixes with a high fat content are more susceptible to partial coalescence than those with a low fat content ([^25]).

6. Summary

Milk fat has a significant effect on the perception of flavour. As a source of flavour, it contributes significantly to the buttery, creamy, and ‘rich’ flavour of ice cream. It is also the main carrier of added flavour, owing to more odour molecules dissolving in fat than in water. Fat also influences the rate of flavour release, the perceived flavour intensity, and the duration of flavour: generally speaking, a higher fat content leads to a slower release of flavour, lower flavour intensity, and a longer duration of flavour.

Milk fat contributes to the smooth and creamy texture of ice cream by lubricating the palate, thereby reducing the perception of coarseness due to large ice crystals. Fat globules also mechanically obstruct growth of ice crystals during storage, thereby slowing the rate of recrystallisation and extending shelf-life.

The partial coalescence of fat globules during dynamic freezing is responsible for stabilising air bubbles, resulting in the beneficial properties of dryness, smooth texture, and resistance to meltdown. Ice cream mixes with a high fat content are more susceptible to partial coalescence than those with a low fat content. Increasing the fat level in ice cream has also been shown to reduce the rate at which ice cream melts during consumption.

7. References

[^1]: Bolliger, S., Goff, D., and Tharp, W., 2000. Correlation between colloidal properties of ice cream mix and ice cream. International Dairy Journal. 10: 303–309.

[^2]: Goff, H. D., 1997. Colloidal aspects of ice cream. International Dairy Journal. 7: 363–373.

[^3]: Granger, C., Leger, A., Barey, P., Langendorff, V., and Cansell, M., 2005. Influence of formulation on the structural networks in ice cream. International Dairy Journal. 15:255–262.[^4]: Goff, H. D., and Hartel R. W., 2013. Ice Cream. Seventh Edition. New York Springer.[^5]: Prindiville, E. A., Marshall, R. T., and Heymann, H., 1999. Effect of milk fat on the sensory properties of chocolate ice cream. Journal of Dairy Science. 82:1425-1432.

[^6]: Maarse, H., and Van den Berg, F. Current Issues in Flavour Research. In: Piggott, J. R., and Paterson, A., eds. 1989. Distilled Beverage Flavour. ). Horwood Ellis

[^7]: Hatchwell, L. C., Implication for fat on flavor. In: McGorrin R. J., & Leland, J. V. eds. 1996. Flavor-food interactions. Washington DC: American Chemical Society. vol. 633. pp. 14–23.[^8]: Li, Z., Marshall, R., Heymann, H., and Fernando, L., 1997. Effect of milk fat content on flavour perception of vanilla ice cream. Journal of Dairy Science. 80:3133-3141.[^9]: Lallemand, M., Giboreau, A., Rytz, A., and Colas, B., 1999. Extracting parameters from time-intensity curves using a trapezoid mode: the example of some sensory attributes of ice cream. Journal of Sensory Studies. 14(4), 387–399.[^10]: Frost, M. B., Heymann, H., Bredie, W. L. P., Diklsterhuis, G. B., and Martens, M., 2005. Sensory measurement of dynamic flavour intensity in ice cream with different fat levels and flavourings. Food Quality and Preference. 16. 305-314.

[^11]: Bayarri, S., Taylor, A. J., and Hort, J., 2006. The role of fat in flavour perception: effect of partition and viscosity in model emulsions. Journal of Agricultural and Food Chemistry. 54.8862-8868.

[^12]: Hyvonen, L, Linna, M., Tuorila, H., and Dijksterhuis, G., 2003. Perception of melting and flavour release of ice cream containing different types and contents of fat. Journal of Dairy Science. 86:1130-1138.

[^13]: Stampanoni Koeferli, C.R., Piccinali, P., and Sigrist, S., 1996. The influence of fat, sugar and non-fat milk solids on selected taste, flavor and texture parameters of a vanilla ice-cream. Food Qual. Pref. 7: 69–79.

[^14]: Hatchwell, L. C., 1994. Overcoming flavor challenges in low-fat frozn desserts. Food Technology. 48.98-102.

[^15]: Guinard, J. X., Zoumas-Morse, C., Mori, L., Uatoni, B., Panyam, D., and Kilara, A., 1997. Sugar and fat effects on sensory properties of ice cream. Journal of Food Science. 62(5).[^16]: Donhowe, D. P., Hartel. R. W., and Bradley, R. L. Jr., 1991. Determination of ice crystal size and distribution in frozen desserts. Journal of Dairy Science. 74.3334-44.[^17]: Fennema, O. R., Powrie, W. D., and Marth, E. H., 1973. Low Temperature Preservation of Foods and living Matter. USA: Marcel Dekker, Inc.[^18]: Walstra, P., 1989. Principles of foam formation and stability. In Wilson, A. J., (Ed), Foams: Physics, Chemistry and Structure. Berlin: Springer.[^19]: Chang, Y., and Hartel, R. W., 2002. Measurement of air cell distributions in dairy foams. International Dairy Journal. 12:463-472.[^20]: Chang, Y., and Hartel, R. W., 2002. Development of air cells in a batch ice cream freezer. Journal of Food Engineering. 55, 71-78.[^21]: Eisner, M. D., Wildmoser, H., and Windhab, E, J., 2005. Air cell microstructuring in a high viscous ice cream matrix. Colloids and Surfaces A: Physicochemical and Engineering Aspects. 263(1)

[^22]: Lin, P. M., and Leeder, J. G., 1974. Mechanisms of emulsifier action in an ice cream system. Journal of Food Science. 39. 108-111.

[^23]: Buchheim, W., Barfod, N. M., and Krog, N., 1985. Relation between microstructure, destabilization phenomena and rheological properties of shippable emulsions. Food Microstructure. 4. 221-232.

[^24]: Berger, K. G., 1990. Ice cream. In Larson, K., and Friberg, S., Food Emulsions, 2nd ed. New York: Marcel Dekker Inc.

[^25]: Hinrichs J., and Kessler, H., 1997. Fat content of milk and cream and effects on fat globule stability. Journal of Food Science. 62: 992-5.

[^26]: McCandlish, A.M., Kilara, A., Macneil, J. H, and Tharp, B. W., 1992. The effects of fat on the sensory attributes of ice cream. Institute of Food Technologists Annual Meeting, Anaheim, CA. Book of Abstracts, p. 10.