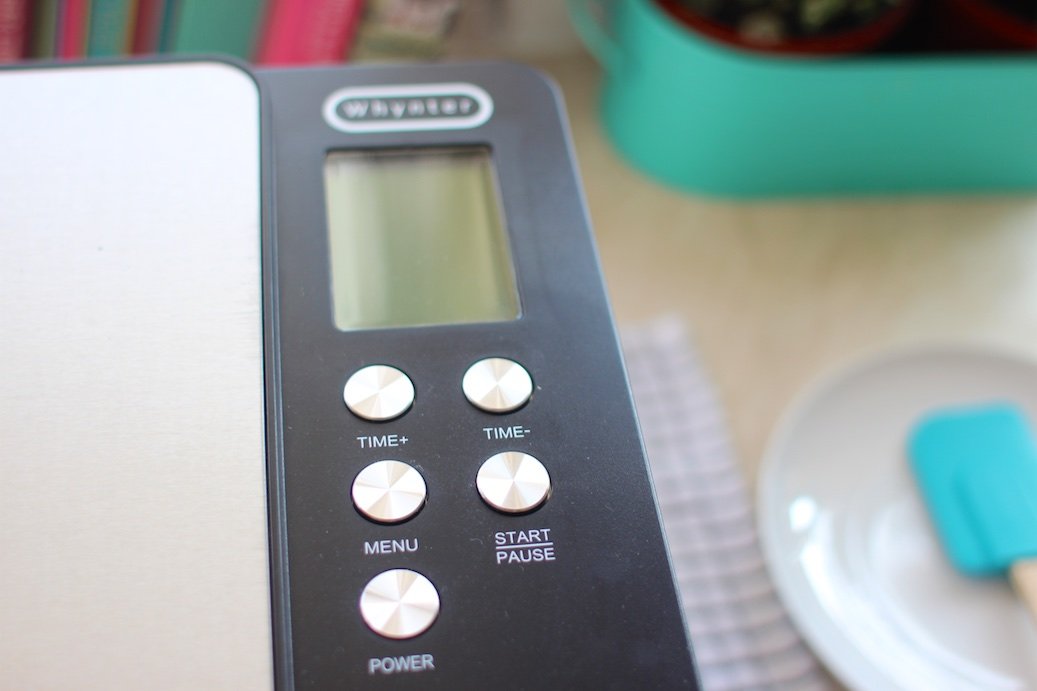

Whynter ICM-200LS Stainless Steel Ice Cream Maker - Review

The Whynter ICM-200LS Stainless Steel Ice Cream Maker, available from [amazon text=amazon&asin=B00N63J432], is a 2.1 quart domestic ice cream maker with a self-refrigerating compressor. It has an impressive 1400 ml (1.48 quarts) maximum capacity, producing about 1600 ml (1.69 quarts) of ice cream with 14% overrun, an optimum capacity of 1000 ml (1.06 quarts), producing about 1100 ml (1.16 quarts) of ice cream with 10% overrun, and produces excellent ice cream that is extremely smooth, dense, and creamy. This will be a comprehensive and impartial review of my experience with the Whynter ICM-200LS Stainless Steel Ice Cream Maker.I'M ALWAYS LOOKING FOR WAYS TO IMPROVE THIS BLOG. PLEASE DO GET IN TOUCH AND LET ME KNOW WHAT YOU DON'T LIKE ABOUT, OR WANT TO SEE INCLUDED IN, THIS REVIEW. RUBEN :)I'd also recommend having a look at the following machines:To view the top selling ice cream makers on amazon, please click here

The Whynter ICM-200LS Stainless Steel Ice Cream Maker, available from [amazon text=amazon&asin=B00N63J432], is a 2.1 quart domestic ice cream maker with a self-refrigerating compressor. It has an impressive 1400 ml (1.48 quarts) maximum capacity, producing about 1600 ml (1.69 quarts) of ice cream with 14% overrun, an optimum capacity of 1000 ml (1.06 quarts), producing about 1100 ml (1.16 quarts) of ice cream with 10% overrun, and produces excellent ice cream that is extremely smooth, dense, and creamy. This will be a comprehensive and impartial review of my experience with the Whynter ICM-200LS Stainless Steel Ice Cream Maker.I'M ALWAYS LOOKING FOR WAYS TO IMPROVE THIS BLOG. PLEASE DO GET IN TOUCH AND LET ME KNOW WHAT YOU DON'T LIKE ABOUT, OR WANT TO SEE INCLUDED IN, THIS REVIEW. RUBEN :)I'd also recommend having a look at the following machines:To view the top selling ice cream makers on amazon, please click here

2. ICE CREAM MIX FORMULATION AND PROCESSINGTo test the Whynter ICM-200LS Stainless Steel Ice Cream Maker, 6 ice cream mixes were formulated to contain 54.9% total solids, 23.3% milk fat, 10.8% milk solids-not-fat (the lactose, proteins, minerals, water-soluble vitamins, enzymes, and some minor constituents), 16.3% sucrose, and 4.4% egg yolks. All mixes contained fresh cream, fresh milk, skimmed milk powder, sucrose, and egg yolk solids. All mixes were heated to 72°C (161°F), held at that temperature for 25 minutes, cooled, and aged overnight at 4°C (39°F). Mix composition was kept constant for all 6 mixes but mix volume was varied from 800 ml (0.85 quarts) to 1400 ml (1.48 quarts). One further mix was made using the Rich Vanilla Ice Cream recipe from the Whynter instruction manual. This recipe contained fresh cream, fresh milk, sucrose, and egg yolks, and followed the same processing stages as the previous 6 mixes. Results from the 7 tests can be seen in section 5.2 of this review.3. OVERRUN

2. ICE CREAM MIX FORMULATION AND PROCESSINGTo test the Whynter ICM-200LS Stainless Steel Ice Cream Maker, 6 ice cream mixes were formulated to contain 54.9% total solids, 23.3% milk fat, 10.8% milk solids-not-fat (the lactose, proteins, minerals, water-soluble vitamins, enzymes, and some minor constituents), 16.3% sucrose, and 4.4% egg yolks. All mixes contained fresh cream, fresh milk, skimmed milk powder, sucrose, and egg yolk solids. All mixes were heated to 72°C (161°F), held at that temperature for 25 minutes, cooled, and aged overnight at 4°C (39°F). Mix composition was kept constant for all 6 mixes but mix volume was varied from 800 ml (0.85 quarts) to 1400 ml (1.48 quarts). One further mix was made using the Rich Vanilla Ice Cream recipe from the Whynter instruction manual. This recipe contained fresh cream, fresh milk, sucrose, and egg yolks, and followed the same processing stages as the previous 6 mixes. Results from the 7 tests can be seen in section 5.2 of this review.3. OVERRUN

Overrun is the calculation of air that's incorporated into frozen desserts and is calculated as the percentage increase in volume of the mix that occurs as a result of the addition of air (Goff & Hartel, 2013). Overrun can range from as low as 20% to as high as 150% in ice cream and 20% to 60% in gelato, with low overrun generally associated with a premium product. Overrun influences the rate of melt down, with ice cream containing a high amount of air (high overrun) tending to melt slowly (Goff & Hartel, 2013), and ice crystal size, with smaller ice crystals observed in ice cream made at low overrun than in the same ice cream made at high overrun (Hartel, 1996; Sofjan & Hartel, 2003).

I've found that the dasher rotates at a low 25 Revolutions Per Minute (rpm), relative to typical speeds of 100-200 rpm in commercial machines, resulting in overrun of about 10% for a 900 ml (0.95 quarts) mix and about 30% for a larger 1200 ml (1.27 quarts) mix. This produces ice cream with a nice, dense texture that isn't very airy.

4. MAXIMUM CAPACITY

The Whynter ICM-200LS Stainless Steel Ice Cream Maker comes with a 2.1 quart aluminium freezer bowl. It has a handle attached, making it very easy to remove. The instruction manual, available by clicking here, states ‘this high capacity unit makes up to two quarts of your favorite frozen dessert in a single batch’. It then appears to give two contradictory maximum capacity levels: 1194 ml (1.26 quarts) and 1400 ml (1.48 quarts). It states 'To avoid overflowing, please ensure that the mixture does not exceed 60% of capacity of the removable mixing bowl as frozen mixture expands'; 60% capacity of 2.1 quarts is 1194 ml (1.26 quarts) of ice cream mix. It then states 'Please make sure that the pre-mixture does not exceed the top dasher of the churn blade to avoid overflowing', which I've found amounts to just over 1400 ml (1.48 quarts) of ice cream mix.

I've found that the Whynter ICM-200LS Stainless Steel Ice Cream Maker has a maximum capacity of 1400 ml (1.48 quarts) of ice cream mix, which increases to 1600 ml (1.69 quarts) of frozen ice cream with about 14% overrun. However, although it's capable of freezing a 1400 ml batch, I've found that it produces the best textured ice cream when the mix volume does not exceed 1000 ml (1.06 quarts), which increases to about 1100 ml (1.16 quarts) with 10% overrun. I've found that above 1000 ml, the ICM-200LS produces ice cream that is slightly coarse but of acceptable quality.

Interestingly, when I decreased the mix volume to 800 ml (0.85 quarts), the texture wasn't as smooth and creamy as that produced using a 900 ml (0.95 quarts) or 1000 ml (1.06 quarts) mix. This was because as the mix hardened, it contracted in the centre of the bowl into a static block that did not make contact with the cold bowl wall, resulting in inefficient heat transfer and lower agitation. I'd therefore recommend freezing between 900 ml (0.95 quarts) or 1000 ml (1.06 quarts) of ice cream mix per batch for optimum results.

5. ICE CRYSTALS IN ICE CREAM

Ice crystal size is a critical factor in the development of smooth texture (Donhowe et al., 1991) with smooth and creamy ice cream requiring the majority of ice crystals to be small, around 10 to 20 µm in size. If many crystals are larger than this, the ice cream will be perceived as being coarse or icy (Drewett & Hartel, 2007; Goff & Hartel, 2013). Ice crystal size is affected by the composition of the ice cream mix and by freezing, with the latter done in two stages: dynamic freezing, where the ice cream mix is frozen in an ice cream machine whilst being agitated to incorporate air, and static freezing, where the partially frozen ice cream is hardened without agitation in a freezer. Ice crystals form only during dynamic freezing and grow during static freezing.

In this review, we'll be looking at the key principles that underpin crystallisation, as well as the effect that the features on the Whynter ICM-200LS Stainless Steel Ice Cream Maker have on these principles. These will include the dasher, the self-refrigerating compressor, and the freezer bowl.

5.1. NUCLEATION

As the aqueous ice cream mix is added to the machine, the refrigerant removes enough heat to bring the mix below its freezing point. A layer of ice then freezes to the wall of the cold freezer bowl causing rapid nucleation, or the birth of small ice crystals (Hartel, 2001). These ice crystals are scraped off the wall by the rotating dasher and scraper blades and dispersed in the middle of the bowl where the mix is warmer and causes the ice crystals to grow and undergo recrystallisation (large crystals growing and fusing together) (Russell et al, 1999; Drewett & Hartel, 2007). Once the warmer mix in the middle of the bowl is cooled sufficiently, some of the ice crystals scraped from the cold ball wall begin to survive and grow.

It’s important to have a high rate of nucleation so as to create as many small ice crystals as possible (Hartel, 1996).

5.1.1. THE DASHER

Nucleation is affected by the rate of heat transfer from the mix to the cold freezer bowl, with a high rate of heat transfer promoting a high rate of nucleation (Hartel, 1996; Goff & Hartel, 2013). Because heat travels more slowly through ice than stainless steel or aluminium, ice building up on the freezer bowl wall acts as an insulator and lowers the rate of heat transfer. Goff & Hartel (2013) note that even a very thin layer of ice remaining on the bowl wall can cause a dramatic reduction in heat transfer. The rotating dasher and scraper blades help promote high heat transfer by scraping off the ice layer that forms on the side of the cold bowl wall. Keeping the scraper blades as close to the bowl wall as possible is therefore important because it prevents ice build up, thereby ensuring efficient heat transfer (Goff & Hartel, 2013).

The Whynter ICM-200LS Stainless Steel Ice Cream Maker comes with a plastic dasher that has a plastic scraper blade and two mixing blades attached. A fundamental flaw common in all domestic machines I've tried is poorly designed dashers leaving a gap between the scraper blades and the bowl wall, resulting in a layer of ice on the bowl wall and inefficient heat transfer. It's only when you get to commercial machines that you find dashers with spring-loaded blades pushed firmly against the side of the bowl. I've found that when fitted onto the central pin in the freezer bowl, the dasher on the ICM-200LS leaves just a very slight gap between the scraper blade and the side of the bowl, and actually makes contact with the bottom right quarter of the bowl wall as it rotates, resulting in minimal ice build up. The ICM-200LS is the only domestic machine I've tried where the scraper blade actually makes contact with the side of the freezer bowl wall, albeit just under a quarter, resulting in good heat transfer. I was impressed by how little ice was left on the bowl wall during testing.

5.1.2. THE SELF-REFRIGERATING COMPRESSOR

5.1.2. THE SELF-REFRIGERATING COMPRESSOR

The freezer bowl temperature is another factor influencing the rate of nucleation and ice crystal size, with lower freezer bowl temperatures promoting higher rates of nucleation and smaller ice crystals. Drewett & Hartel (2007) found that decreasing the coolant temperatures at the freezer bowl wall caused higher ice crystal nucleation rates and reduced recrystallisation in the warmer bulk mix, which helped the ice crystals remain small. Similarly, Russell et al. (1999) found that as the freezer bowl temperature was lowered, the nucleation rate increased accordingly. Cook & Hartel (2011) simulated ice cream freezing in an ice cream machine by freezing ice cream mix in a thin layer on a microscope cold stage. The temperature at which ice cream mix was frozen on the cold stage varied from -7, -10, -15, and -20°C (19, 14, 5, and -4°F). They found that warmer freezing temperatures gave more elongated and slightly larger crystals with a wider size distribution.

To promote rapid nucleation, the temperature of the refrigerant should fall within the range of -23 to -29°C (-10 to -20°F) (Goff & Hartel, 2013), with the freezer bowl wall temperature estimated to be a few degrees warmer. I've found that the compressor on the Whynter ICM-200LS Stainless Steel Ice Cream Maker is able to get the freezer bowl temperature down to an impressive -36°C (-32.8°F) when empty. This I achieved by using the pre-chill button and leaving the machine running for 15 minutes before adding the mix.

TIP #1 - LOW FREEZER BOWL WALL TEMPERATUREIt’s a good idea to leave the compressor running for about 15 minutes before you add the ice cream mix. This will ensure that the bowl is as cold as possible when the mix is added and help promote higher rates of nucleation and a shorter residence time.

5.2. RESIDENCE TIME

Residence time, that is the length of time the ice cream mix spends in the freezer bowl during dynamic freezing, has a significant effect on the final ice crystal size distribution, with longer residence times resulting in larger ice crystals (Russell et al., 1999; Goff & Hartel, 2013; Drewett & Hartel, 2007; Cook & Hartel, 2010). Russell et al. (1999) showed that residence time in the freezer bowl had a more important impact on final crystal size distribution than did the initial nucleation rate. A similar study by Drewett & Hartel (2007) also concluded that residence time has the greatest impact on final crystal size distribution, followed by draw temperature and dasher speed. This is because a longer residence time gives the ice crystals in the centre of the freezer bowl more time to recrystallise and grow larger (Russell et al., 1999; Drewett & Hartel, 2007).

A high rate of heat transfer and colder freezer bowl temperatures contribute significantly to shorter residence times. Lower freezer bowl wall temperatures can lower the bulk temperature of the ice cream faster, reducing residence time and improving the ice crystal size distribution (Russell et al., 1999; Drewett & Hartel, 2007). Commercial machines usually take between 8-10 minutes to freeze a large batch, ranging from 3 to 44 quarts, of ice cream. Below are the results from my residence times tests.

1. MY MIXMix volume: 800 ml (0.85 quarts).Frozen volume: About 850 ml (0.90 quarts).Overrun: About 6%.Residence time: 29 minutes.Draw temperature: -9°C (15.8°F).Texture: Smooth and creamy with little bits of coarse ice cream.

2. WHYNTER'S RICH VANILLA ICE CREAMMix volume: Just under 900 ml (0.95 quarts).Frozen volume: About 1100 ml (1.16 quarts).Overrun: About 22%.Residence time: 29 minutes.Draw temperature: -9°C (15.8°F).Texture: Very smooth and creamy but a heavy and lingering fat taste.

3. MY MIXMix volume: Just under 900 ml (0.95 quarts).Frozen volume: About 950 ml (1.00 quarts).Overrun: About 8%.Residence time: 28 minutes.Draw temperature: -10°C (14°F).Texture: Really nice, smooth, and creamy. Quite heavy and not very airy.

4. MY MIXMix volume: Just under 1000 ml (1.06 quarts).Frozen volume: About 1100 ml (1.16 quarts)Overrun: About 10%.Residence time: 27 minutes.Draw temperature: -10°C (14°F).Texture: Really smooth and creamy.

5. MY MIXMix volume: 1100 ml (1.16 quarts).Frozen volume: About 1200 ml (1.27 quarts).Overrun: About 9%.Residence time: 33 minutes.Draw temperature: -10°C (14°F).Texture: Quite smooth and creamy with slightly coarse bits. Not bad, just not the smoothest I've tried.

6. MY MIXMix volume: 1200 ml (1.27 quarts).Frozen volume: About 1500 ml (1.59 quarts).Overrun: About 27%.Residence time: 38 minutes.Draw temperature: -10°C (14°F).Texture: Smooth and creamy with definite coarse bits.

7. MY MIXMix volume: Just under 1400 ml (1.48 quarts).Frozen volume: About 1600 ml (1.69 quarts).Overrun: About 14%.Residence time: 39 minutes.Draw temperature: -9°C (15.8°F).Texture: Not bad at all but not the smoothest I've tried. Quite coarse.

Below are the residence times for domestic ice cream machines I’ve tried, along with links to my reviews. Do bear in mind that the greater the batch size, the longer the residence time is likely to be.

Lello Musso Pola 5030 Dessert Maker: 900 ml (0.95 quarts) mix – 13 minutes.Lello 4080 Musso Lussino: 600 ml (0.63 quarts) - 16 minutes.Cuisinart ICE-100 Ice Cream and Gelato Maker: 900 ml (0.95 quarts) mix – 35 minutes.Breville BCI600XL Smart Scoop Ice Cream Maker: 700 ml (0.74 quarts) - 33 minutes.Cuisinart ICE 30BC: 900 ml (0.95 quarts) mix – 35 minutes.KitchenAid K45SS: 900 ml (0.95 quarts) – 30 minutes.DeLonghi GM6000 Gelato Maker: 500 ml (0.53 quarts) 30 minutes.

Although residence time has a significant effect on the final ice crystal size distribution, a short residence time won’t guarantee smooth and creamy texture. The quality of homemade ice cream is, in my experience, more dependent on the recipe than on the machine you use. You might find it useful to have a look through my Vanilla Ice Cream Recipe to get an idea of mix composition.

5.3. DRAW TEMPERATURE

Draw temperature refers the temperature at which ice cream is removed from the freezer bowl and is usually -5 to -6°C (23 to 21.2°F) in commercial machines (Goff & Hartel, 2013). Draw temperature determines how much ice is frozen, with between 33 and 67% of the water in the mix being frozen during dynamic freezing and the hardening stage accounting for an additional 34-57% (Goff & Hartel, 2013). Caillet et al. (2003) showed that decreasing draw temperature resulted in more water being frozen and, consequently, increased ice crystal content. Similarly, Drewett & Hartel (2007) note that draw temperature significantly influences mean ice crystal size. They showed that ice crystals were larger at draw temperatures from -3 to -6°C (26.6 to 21.2°F). When the draw temperatures were colder than -6°C (21.2°F), the mean ice crystal size decreased.

To attain a low draw temperature, the freezer bowl temperature must be low to give rapid heat removal. Rapid heat removal allows for faster ice nucleation rates, which results in smaller ice crystals (Berger et al., 1972). I've found that the Whynter ICM-200LS Stainless Steel Ice Cream Maker has an impressive draw temperature of -10°C (14°F) for mixes between 900 ml and 1200 ml (0.95 quarts and 1.27 quarts). With a larger 1400 ml (1.48 quarts), draw temperature drops to -9°C (15.8°F).

5.4. EXTRACTION TIME

To quickly review, we know that ice crystal size is critical for the development of smooth texture, with small ice crystals imparting smooth and creamy texture, whilst many large ice crystals impart coarse or sandy texture. A high rate of nucleation, a short residence time, and a low draw temperature play a significant role in promoting and maintaining small ice crystals and these three factors are governed by heat transfer and the freezer bowl temperature, which are, in turn, affected by the dasher and the self-refrigerating compressor.

At draw temperature of between -5 and -6°C (23 and 21.2°F), ice cream will have a consistency very similar to that of soft serve ice cream. Ice cream is usually served in its scoopbable state at around -12°C (10.4°F) and so requires further freezing, or hardening. This is known as the static freezing stage and its aim is to preserve the small ice crystals and air cells formed during dynamic freezing. The extraction time, that is the time it takes to empty the ice cream from the machine and get it into your freezer for hardening, is another factor that has a significant effect on ice crystal size.

As you extract your ice cream from the bowl, it spends time at room temperature. During this time at relatively warm room temperature, some of the ice melts from the large ice crystals and the crystals that were initially small melt completely. This is known as ripening and occurs when ice cream is held at elevated temperatures (Goff & Hartel, 2013). When you then get your ice cream into your freezer for hardening, the melted ice re-freezes onto the large ice crystals that survived. The result is that the total number of ice crystals is reduced and their size increases, resulting in coarse or sandy texture. Just holding your ice cream at room temperature, therefore, results in an increase in mean ice crystal size.

5.4.1. THE FREEZER BOWL

I've found that because of the space in the large 2.1 quart bowl, it's extremely quick and easy to extract the ice cream using a large wooden spoon. I haven't had any problems removing the dasher before commencing extraction, which I find speeds up extraction. On some machines I've tried, removing the dasher is impossible either because the design makes it difficult to grip, or because the hardened ice cream traps it in the bowl. I've found, however, that extraction takes considerably longer when freezing a large 1400 ml (1.48 quarts) mix. This is because the increased mix volume hardens and prevents the dasher from being removed.

TIP #2 - QUICK EXTRACTION TIMEIt’s important that you extract your ice cream from the freezer bowl and get it into your freezer as quickly as possible. This is to minimise the time it spends at relatively warm room temperatures, where ice cream starts to melt, thereby limiting ice crystal growth during hardening.

5.5. THE STATIC FREEZING STAGE

5.5. THE STATIC FREEZING STAGE

When you extract your ice cream at between -6°C and -10°C (21.2°F and 14°F), significant changes to the ice crystals continue to take place until the temperature decreases to -18°C (-0.4°F), preferably -25°C to -30°C (-13 to -22°F) (Goff & Hartel, 2013) to halt these changes. Marshall and others (2003) note that during static freezing, ice crystals grow by about 30% to 40%. Donhowe (1993) showed that faster cooling of ice cream during hardening resulted in smaller mean ice crystal size.

TIP #3 - FAST COOLINGTo promote faster cooling of your ice cream during static freezing, it’s important to ensure that your freezer is set to its coldest temperature. If you have a super chill button, or something similar, it's a good idea to switch this on.

It's also a good idea to place your empty plastic container in the freezer a couple of hours before you start churning a batch. This will remove any heat stored in the container and will help prevent ice crystals that come in contact with the relatively warm plastic during the extraction stage from melting.

6. CLEANING

I've found cleaning the Whynter ICM-200LS Stainless Steel Ice Cream Maker very quick and easy. I haven't had any problems cleaning the removable bowl and dasher with warm soapy water. Whynter do note that the bowl, dasher, lid, and plastic scoop are not dishwasher safe.

7. NOISE LEVEL

Whynter note that the ICM-200LS produces less than 58 dB of noise but I've found this to be closer to 72 dB during freezing, which I haven't found a problem. I've found the ICM-200LS S quiet during freezing and haven't had any problems with sitting in the same room with it on.

8. ISSUES RAISED BY USERS

Two pertinent issues that have been raised by users in their reviews on amazon are a squeaking noise and the dasher grinding to a halt before the ice cream has hardened sufficiently.

8.1. SQUEAKING NOISE

Several users have complained that their ICM-200LS makes a squeaking noise during freezing. The first time I froze a 900 ml (0.95 quarts) mix, I did find that the dasher made a squeaking noise as the mix hardened. This was due to the top of the dasher rubbing against the small plastic support tube in the lid. Surprisingly, I only encountered this noise the first time I froze a 900 ml (0.95 quarts) and haven't encountered it since. I presume this issue was due to an initial teething problem.

8.2. DASHER GRINDING TO A HALT

The second issue that has been raised by several users is the dasher clicking and stopping before the mix has had sufficient time to harden. Throughout my testing, I've noticed that the dasher does start to slip a minute or two before a draw temperature of -10°C (14°F) is reached. I've found this to be because the teeth on the gear that drives the dasher, and the teeth on the underside of the freezer bowl, are quite small and slip as the mix hardens. This problem is annoying but I've found that it doesn't prevent the mix from being sufficiently hardened nor a draw temperature of -10 (14°F) from being reached. I would, however, like to see bigger teeth on the driving gear and on the underside of the bowl on a future Whynter model to prevent this problem.

9. THE QUALITY OF THE ICE CREAM

I’ve found that the Whynter ICM-200LS Stainless Steel Ice Cream Maker produces excellent ice cream that is extremely smooth and creamy when an optimum 900 ml to 1000 ml (0.95 quarts to 1.06 quarts) of mix is frozen. Above or below this optimum range, I've found that texture becomes a little coarse. It produces ice cream with about 10% overrun that's dense and doesn't feel airy in the mouth.

10. FINAL THOUGHTS

I've found that the Whynter ICM-200LS Stainless Steel Ice Cream Maker produces excellent ice cream that is extremely smooth, dense, and creamy. It has an optimum capacity of 900 ml to 1000 ml (0.95 quarts to 1.06 quarts) of ice cream mix, producing about 950 ml (1.00 quarts) and 1100 ml (1.16 quarts) respectively of frozen ice cream with about 10% overrun. The powerful compressor is able to get the removable bowl to an impressive -36°C (-32.8°F) when empty and the large 2.1 quart bowl makes extracting the frozen ice cream extremely quick and easy. It's the only domestic machine I've tried whose scraper blades make contact with the side of the freezer bowl, resulting in minimal ice build and good heat transfer.

It is, however, by no means perfect. Although it's capable of freezing a large 1400 ml (1.48 quarts) mix, I've found that above the optimum 900 ml to 1000 ml (0.95 quarts to 1.06 quarts), it produces ice cream that is slightly coarse. The small teeth connecting the rotating gear and dasher are quite small and slip towards the end of the dynamic freezing stage.

Transparency is key. On that note, I haven't been paid to write this review, nor was I given this machine for free. I paid for this bad boy with my own money and have written this review in my own time. If there is a * after a link, it means that I will earn a payment if you go through it and make a purchase on amazon. This doesn't increase the cost of what you purchase, nor do these links influence what I write, ever.

11. COMPARABLE MACHINES

11.1. NON-COMPRESSOR MACHINES

For the home cooks looking to spend less on an ice cream machine, I’d recommend having a look at the [amazon text=Cuisinart ICE 30-BC&asin=B0006ONQOC&asin[uk]=B001D650FA&asin[de]=B002007HQI&asin[fr]=B002007HQI&asin[es]=B002007HQI&asin[it]=B002007HQI&asin[ca]=B0006ONQOC]. It makes excellent ice cream but requires the freezer bowl to be frozen overnight before use. You'll also need a freezer capable of getting the temperature down to around -25°C (-13°C). This is to ensure that the freezer bowl wall temperature falls between -23 to -29°C (-10 to -20°F), the temperature range necessary to promote rapid nucleation and shorter residence times.

11.2. COMPRESSOR MACHINES

The [amazon text=Cuisinart ICE-100 Ice Cream and Gelato Maker&asin=B006UKLUFS&asin[uk]=B00ARETWDK&asin[de]=B00ARETWDK&asin[fr]=B00EDOVBP2&asin[es]=B00EDOVBP2&asin[it]=B00ARETWDK&asin[ca]=B006UKLUFS] makes excellent ice cream but has a slightly lower optimum capacity of 800 ml (0.85 quarts), producing about 1000 ml (1.06 quarts) of ice cream with 25% overrun. The [amazon text=Breville BCI600XL Smart Scoop Ice Cream Maker&asin=B009OZ62IG&asin[ca]=B009OZ62IG&asin[uk]=B00CI32S0W&asin[de]=B00HFQDG5I&] also makes great ice cream but also has a smaller optimum capacity of 700 ml (0.74 quarts), producing about 900 ml (0.95 quarts) of ice cream with about 29% overrun.

The [amazon text=Lello 4080 Musso Lussino 1.5-Quart Ice Cream Maker&asin=B00004RDF0&asin[ca]=B00004RDF0&asin[uk]=B00004RDF0&asin[de]=B00004RDF0&asin[it]=B00004RDF0&asin[es]=B00004RDF0&asin[fr]=B00004RDF0] has a smaller optimum capacity of 600 ml (0.63 quarts) but a shorter residence time of 16 minutes and makes exceptional ice cream. The [amazon text=Lello Musso Pola 5030 Dessert Maker&asin=B000FIWZLO&asin[ca]=B000FIWZLO&asin[uk]=B004S7BHE4&asin[de]=B004S7BHE4&asin[fr]=B004S7BHE4&asin[it]=B004S7BHE4] has an impressive 1300ml (1.37 quarts) maximum capacity, makes exceptional ice cream that is extremely smooth, dense, and creamy, and at 13 minutes has the shortest residence time of any domestic machine I've tried.

I hope that helps. I’d be happy to answer any questions so do get in touch and say hi! All the best, Ruben :)

References

Berger, K. G,, Bullimore, B. K., White, G. W., & Wright, W. B., (1972). The structure of ice cream – Part 1. Dairy Industries, 37(8), 419-425.

Caillet, A., Cogne, C., Andrieu, J., Laurent, P., Rivoire, A., 2003. Characterization of ice cream structure by direct optical microscopy. Influence of freezing parameters. Lebensm Wiss U Technol. 36:743–749.

Cook, K. L. K., & Hartel, R. W., 2010. Mechanisms of Ice Crystallisation in Ice Cream Production. Comprehensive Reviews in Food Science and Food Safety. 9(2).

Cook, K. L. K., and Hartel, R. W., 2011. Effect of freezing temperature and warming rate on dendrite break-up when freezing ice cream mix. International Dairy Journal. 21(6).

Donhowe, D. P., Hartel R. W., and Bradley R.L., 1991. Determination of ice crystal size distributions in frozen desserts. Journal of Dairy Science. 74.

Donhowe, D. P. (1993) Ice Recrystallization in Ice Cream and Ice Milk. PhD thesis, University of Wisconsm-Madison.

Drewett, E. M., & Hartel, R. W., 2007. Ice crystallisation in a scraped surface freezer. Journal of Food Engineering. 78(3).

Goff, H. D., and Hartel R. W., 2013. Ice Cream. Seventh Edition. New York Springer.

Hartel, R. W., 1996. Ice crystallisation during the manufacture of ice cream. Trends in Food Science & Technology. 7(10).

Hartel, R. W., 2001. Crystallisation in foods. Gaithersburg, MD: Aspen Publishers.

Marshall, R. T., Goff, H. D., and Hartel R. W., 2003. Ice cream (6th ed). New York: Kluwer Academic/Plenum Publishers.

Russell, A. B., Cheney, P. E., & Wantling, S. D., 1999. Influence of freezing conditions on ice crystallisation in ice cream. Journal of Food Engineering. 29.

Sofjan, R., P., and Hartel, R. W., 2003. Effects of overrun on structural and physical characteristics of ice cream.International Dairy Journal. 14, 255-262.